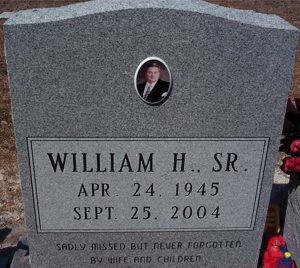

I

imagine you’ve seen these before. I am not particularly

fond of porcelain for several reasons I’ll elaborate

on later. We experimented with porcelain for some time

before moving forward with the development of our high

resolution etching on stainless and titanium. We actually

got porcelain to adhere extremely well to titanium in the

lab.

I

imagine you’ve seen these before. I am not particularly

fond of porcelain for several reasons I’ll elaborate

on later. We experimented with porcelain for some time

before moving forward with the development of our high

resolution etching on stainless and titanium. We actually

got porcelain to adhere extremely well to titanium in the

lab.

As

you may know porcelain has been around for centuries. It

has been in use in China for over 4,000 years. The Chinese

probably made the first true porcelain during the Tang dynasty

(618-907). Transfer printing revolutionized the porcelain

industry in 1756. Recent advances in printing technology

now enable us to print decals from desk top printers using

what they call porcelain inks.

The Porcelain

Enamel Institute does a lot of research

on porcelain. Following are two excerpts from their Web

site.

“ IMPACT

RESISTANCE

Like

glass, porcelain enamel will fracture when abused. It is

difficult to predict the impact resistance of a specific

porcelain enamel since it depends as much or more on the

design of the part as on the properties of the porcelain

enamel.

WEATHER

RESISTANCE

The

weatherability of porcelain enamel is usually measured

by the degree to which the coating retains its original

gloss and color. In general, acid resistant porcelain

enamels have better weather resistance than those that

are non-acid resistant. Thus, those porcelain enamels to

be exposed to weathering should be specified to have no

less than a Class A acid resistance rating.

The

weatherability of porcelain enamel is usually measured

by the degree to which the coating retains its original

gloss and color. In general, acid resistant porcelain

enamels have better weather resistance than those that

are non-acid resistant. Thus, those porcelain enamels to

be exposed to weathering should be specified to have no

less than a Class A acid resistance rating.

Glossy,

acid resistant porcelain enamels have shown no appreciable

change in appearance after 15 years exposure. However, similar

exposure may substantially change the appearance of some

matte and non-acid resistant porcelain enamels. Some types

of highly pigmented red and yellow

porcelain enamels may

show some fading after several years of weathering.”

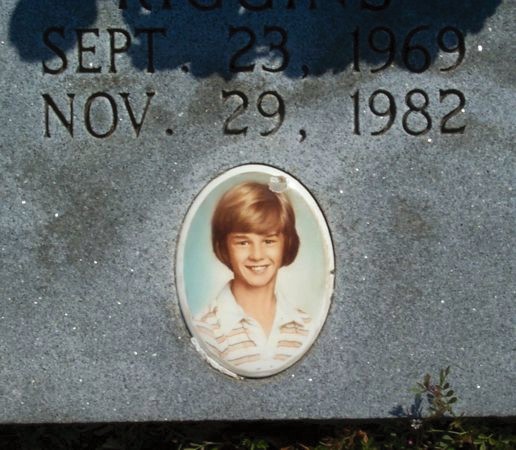

Several

cemetery managers mentioned to me that they noticed some

of the porcelain tributes fading. This may be due in part

to the chemistry now used in the inks developed for the transfers.

Also EPA regulations have come into play. Cobalt and cadmium,

used as pigments, are considered neurotoxins that can damage

the liver and kidneys. Some of the strong inorganic oxides

that gave original porcelain its permanence now are becoming

off limits because of disposal regulations or air contamination

during use. Old porcelain didn’t fade. Apparently the

newer items do.

Personally,

I feel a full color image, essentially a color photograph,

is tacky when mounted to a fine stone or bronze memorial.

In addition, porcelain does

break. The photo below shows chips in the

tribute made by rocks or other flying debris. If you dropped

a brick on a porcelain tribute manufactured using a thin

gauge substrate and a brick on a Diamond Memory™ there

would be different consequences. The porcelain would be severely

compromised. The Diamond Memory™ may end up with a

small dent.

The

other thing you must be careful about when purchasing a porcelain

tribute is the metal on which the porcelain is fired. Some

dealers use high carbon steel. If the porcelain gets chipped

the steel underneath will begin to rust. That rust can continue

unabated under the porcelain on the back side of the metal

until all that’s

left is a porcelain shell - like an egg. I’ve heard

that some manufacturers use stainless as a base metal. If

you

buy one of these tributes, make sure what type of metal

and its gauge is being used. We use .060 316L stainless.

To

keep them from chipping you can purchase a separate cover

arrangement, like a little door. I think that defeats the

intention. Not many people are going to open the door to

look at the photo.

The

other area of concern is the mounting. Some porcelain tributes

come with an epoxy tape. The tribute is simply stuck to the

stone. In some cases cemeteries don’t use the tape

and affix the tribute with epoxy paste. Either way it's a

surface mount, which in time, due to expansion and contraction

coefficients, and potential microbial attack and UV degradation

along the edges, will lose adhesion and fall off. Who is

going to put it back on? This is not as much of a problem

if the tribute is mounted horizontally

on a flush bronze or stone memorial. Attachment methodology

is something to consider when thinking far into the future.

Chipped by rocks thrown by lawnmower.

MEMORIAL

/ HEIRLOOM TRIBUTES

The

techniques used to produce porcelain items these days must be

taken into consideration. Many porcelain dealers

offer memorial tributes, heirloom plates and jewelry. These

are very nice and make a great addition to the home. When

we talk about extreme longevity, breakage and other circumstances

must be taken into consideration. Are the images reproduced

using transfer decals? If decals are used, are they considered

no fire or low fire. Following is some

points to consider.

"ART

186 – Intro To Ceramics

Glendale Community College, 1500 North Verdugo Road, Glendale,

California 91208

Steps in the ceramic process

(Section relating to low temperature ceramic decals)

OVERGLAZE FIRING

Sometimes,

potters choose to do additional firings to achiever color

and surface effects not possible in the glaze firing.

These effects include lusters, china paints and decals.

These overglaze techniques are fired at extremely low temperature

(1300 degrees F.) and because of that, brighter colors and

lusters are possible than can be achieved at 2350 degrees F.

These are, loosely speaking, very low fire glazes that

are melted atop the previously fired high temperature glaze.

At

this low temperature, the underlying glaze does not even melt,

instead the luster, china paint, or decal melt onto

the glaze and fuse, semi-permanently.

This is the major

disadvantage of this technique. The

overglazes are not

as permanent as high

temperature glazes. Abrasion will erode

this coating, and eventually, the overglaze will be gone or

muted by time. Still, unusual

and exotic effects are possible, and for this reason, potters

are interested in this area. Some techniques, like china painting,

often involve multiple overglaze firings, layering one color

on top of another as complicated designs emerge."

Due

to advances in recent technology, photographic, high resolution

images on porcelain and ceramic pieces are probably produced

using transfer decals. Some transfer decals are no fire.

They are transferred and oven baked at 300 degrees Fahrenheit.

Their

durability

is limited based on usage. Then you have the low fire decals

which are kiln fired at 1,300 to 1,540

degrees

Fahrenheit. If these pieces are kept inside and not broken

or exposed to severe abrasion or extreme UV, they should

last indefinitely.

I would not recommend no fire decal transfers

for outdoor use.

January

20, 2013: We are working on a ceramic on

metal option using low fire ceramic decals

that may possess extreme durability in outdoor environments.

Stay tuned for updates.